Place of Origin:

China (CN)

Brand Name:

ABB

Certification:

CE

Model Number:

UT

Contact Us

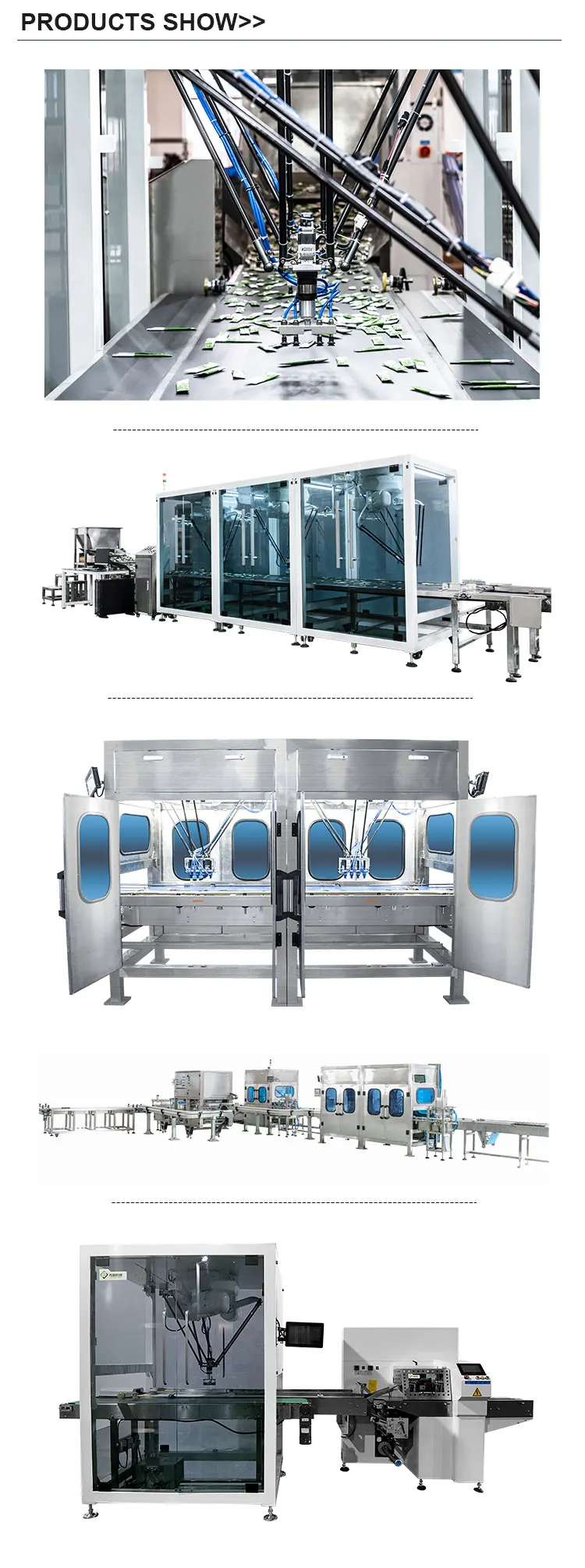

Robot arm soft fixture picking and placement system. Repeatability:±0.1mm

Main Feature:

Its body material is mainly made of carbon fiber and aluminum alloy composition.

It can accurately identify the target object through a sensor or visual system, motion tracking, picking and placing the target object to the designated position.

The high-speed handling unit with robot functionality for free movement in three dimensions provides precision in movement and positioning as well as a high dynamic response of up to 180 picks/min.

The highly rigid mechanical design and low moving mass make the parallel delta kinematic system with toothed belt axes up to three times as fast as comparable Cartesian systems.

Three double rods keep the front unit horizontal at all times. The axes and servo motors do not move with the unit.

The parallel kinematic system is suitable for handling loads of up to max. 5 kg.

The 'picking and releasing' system consists of a standard industrial robotic arm and customized grippers and suction cups equipped by researchers. Researchers have developed a gripping algorithm that enables robots to determine the optimal way to grab or adsorb randomly placed objects without having to accurately understand the objects before picking them up.

Product Introduction

Carbon fiber and aluminum alloybody structure.

High dynamic response up to80 pick/minute.

Machine learning, deep learning, CNN, visual system: Motion tracking.picking and placing to the target position.

Three double rods design:Axes and servo motors move separately.

Parallel delta kinematic system three times as fast as Cartesian systems.

Sorting the sachets according to the front and back , up and down of the packingPicking and placing sachet onto the conveyor belt or into the piling up device:Loading the sorted sachets into the inner boxes.

DESCRIPTION

We can customize the delta robot packaging system specially to meet yourrequirements. The delta robot packaging system has the great advantages in theaspects of fast speed, high accuracy, reliable performance, small occupation spaceand low maintenance cost. lt is widely used in the pharmaceutical and food.

![]()

About the company

Our guide rail has cooperated with many international well-known robot brands, such as ABB KUKA FANUC Yaskawa UR. The companies involved mainly include palletizing, loading and unloading. The load of the guide rail ranges from 500kg to 5000kg. The length of the guide rail is customized according to the needs of customers. We have made a case that an ABB IRB6700 robot corresponds to 20 CNC machines, and a 50m long guide rail completes the reciprocating motion, loading and unloading of the robot. The number of robots is greatly reduced and the integration cost is saved.

Our company also offers industrial robots at very favorable prices to place orders together at lower prices.

Welcome to Shanghai, China, to investigate our robots and rails!

Company Product Supply

ABB robot

KUKA robot

Yaskawa robot

Fanuc robot

UR robot

Cobot

Guide rail

Cobot made in China

Product specifications

Product parameters table

![]()

Packaging and Transportation

![]()

![]()

Send your inquiry directly to us